Are you an optician looking to set up an in-office lab or a lab owner wanting to invest in the best lens edger machine?

Yes? Well, this article has everything covered.

Read on.

The optical retail industry has witnessed a tremendous shift in consumer behavior in this decade. Buyers in the present time are reluctant to wait for their purchase to reach their hands adding immense pressure on retailers, lab owners, and manufacturers. Business owners are thriving to mitigate consumer demands at the earliest to be able to earn a profit.

Undoubtedly, the competition is cutthroat. In order, to reduce the fulfillment time gaps having the right machinery at your premise is essential.

When talking about machinery for an optical lab, a Lens Edger Machine is inevitable. Let’s start edging.

What is a lens edger?

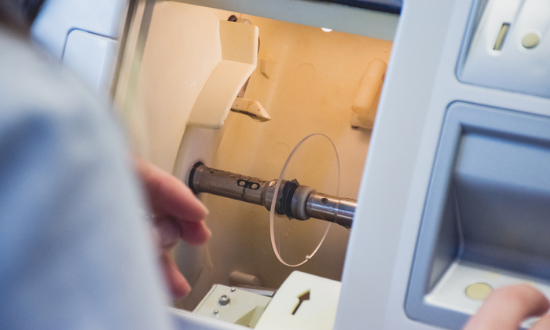

An ophthalmic lens is a round disc-like glass with power correction. As you already know, it needs to be altered to fit in the spectacle frame chosen by the buyer. A lens edger is a machine that cuts the ophthalmic lens and shapes it accordingly to fit the eyeglasses.

There are basically three types of lens edger to choose from i.e. Auto lens edger, Semi-automatic lens edger, and Manual lens edger. The basic functionality remains the same; edging different shapes and sizes of the lens. For bigger labs, tabletop lens edger cannot support their production level hence industrial lens edger is more suitable.

Is a stand-alone lens edger enough?

The process of edging a lens requires more than just a lens edger machine for more precise and accurate edging.

Blocker

The blocker allows you to ensure exact height during edging and prepares your lens for the shaping process.

Tracer

The shape of the eyeglasses and its dimensions are determined by the Tracer. The lens edger machine cuts and shapes the lens in accordance with the measurement indicated by your tracer during the process.

Lensometer

Further, the edging procedure is impossible without a lensometer confirming the lens’ power to correct the eye condition of the patient. A lensometer gives an accurate reading of the power of the lens in various settings.

These equipments together with the lens edger machine give a more accurate cutting of the lens. Delivering eyeglasses timely without compromising the quality can be made possible with these machines.

Top lens edger machines

Huvitz

If you are looking for a complete edging solution, Huvitz Excelon is what you need. With its 3D digital technology, you can manage multiple processes and yet achieve greater productivity. Whether it is blocking, tracing, or edging Excelon integrates it all.

Further, the machine holds 4 grinding wheels for different lens materials. It is ideal for an in-office lab setup.

Features

Read more accurately with built-in Tracer with 3D measuring

You can choose between Auto or Semi-Auto or Concave mode. In Semi-Auto mode, the stylus can be manually positioned in the narrow groove of difficult eyeglasses. In Concave mode, the concave shape demo lens is identified. Tracing frames and cutting lenses at the same time improve efficiency and reduce the overall job time substantially

Hydrophobic Lens edging is made easier

When working with ultra-water-repellent coated lenses that are prone to slipping and deflection, processing alternatives including roughing, safety mode, pressure control of the adaptive clamp chuck, and lens rotation speed can all be balanced and operated simultaneously.

Adaptive Clamp Chuck

Reduce axis twist and prevent lens and coating damage when processing high-curved Lenses. Also, you can choose between automatic 3-step pressure adjustment i.e. high, medium and low, or manual input adjustment from 50 to 150 percent.

Different Feeling Modes

- Optimal feeling positioning in a number of settings and conditions, such as measuring in normal mode, changing spectacles, and checking for Bevel shortfall.

- Three feeling position modes: both sides, front for CAP lenses, and rear for EX lenses.

- Safety bevel or grooving quality feeling option after roughing.

Drilling and Ultem mode

Secure and stable 12-degree drilling is assimilated, enabling for one-touch setup and auto-run.

Ultem mode is a customized mode for extremely soft eyeglasses.

Nidek

Achieve greater perfection with Nidek’s new ME 1500 Multifunction lens edger machine. Its user-friendliness is quite remarkable. Entering data is simplified with a full-width display and jog dial. This type of auto edger is most suitable for in-office labs or small labs. Nidek offers a range of industrial edgers such as Auto edging system, System Dry Edger, Auto Dry edging system, and more that offer higher throughput.

Features

Auto 3D drilling

Drilling holes in the lens is required to connect the temples of the eyeglasses. With automatic 3D drilling, you can drill various holes such as a counterbored hole, jewel hole, slots, and notches.

High base curve lens processing

ME 1500 offers manual control for adjusting the position and height of the bevel. With its independent front and rear grinding outstanding finishing is achieved for high-base curve lens processing.

Customizable beveling

Asymmetrical bevels, which are highly customizable, allow lenses to be perfectly fitted into a variety of eye wires. Mini beveling is also accessible with a single button press.

Step beveling

Rx lenses can be conveniently placed into sunglasses that were previously hard to fit thanks to step beveling. Rx lenses for specialty-type sports eyewear are grinded in a partial step process.

Design

Customized lens shapes can be created by using a drill bit as a milling tool.

Essilor

Mr Blue by Essilor is at the forefront of innovation and has been a true ECP partner since its inception. Mr Blue is the ideal solution for demanding workshops, now with a plethora of new functions and even greater flexibility.

Features

Complete mounting control

Grinding together with milling technology gives full axis control.

Ideal for high-base curve mounting

Mr. Blue allows binocular 3D tracing of full-rim eyeglasses with 9 base. Centering can be automatically adjusted based on parameters. Further, roughing cycle adapts the curve of the lens up to base 10.

Wide range of bevels

The height of the bevel can be adjusted to fit thinner as thicker grooves perfectly. The shelf bevel heights are optimized to precisely follow the shape of the eyewear. The step bevel is ideal for sports glasses with a deep, rectangular, or uneven groove profile.

Flexibility in processes and configurations

Processes are enhanced to ensure high productivity and quality irrespective of materials, coatings, or shapes.

Easy UI

Mr. Blue 2.0 interfaces seamlessly with other systems and hardware in your practice with Essibox. It is not required to enter data over and over again. The remainder of the cycle times is shown by Mr. Blue 2.0.

Satishloh

Satisloh’s ES-5 wet cutting, blockless optical lens edger operates on all lens material types and has an extremely long tool life, setting the industry standard for the lowest consumable cost per lens.

Features

Blockless lens edging

It offers all-in-one lens production that is automated, stable, dependable, and accurate, including grooving, safety beveling, and front-side drilling. Its roughing time dynamically adjusts to the Rx of the lens.

Auto lens edging

Grooving equipment with a small diameter range and quick and precise drilling angles ranging from 0 to 75 degrees around 0.7mm to 1.2mm

Full automation improves performance and versatility while reducing operator interaction reduces breakage.

An automated lens monitoring system, or LIS, tests Rx strength and lens cut-out, minimizing the need for additional inspection measures prior to edging. It senses and investigates low-power single vision and prismatic lenses with ease, ensuring accurate de-centration for both lenses.

Conclusion

In-house lens edging is gaining momentum in the present time. Though it saves you from lab bills, you do need to bear investment in machinery. The biggest benefit is you deliver complete eyewear to your customers or practitioners at the earliest.

For lab owners, Nidek offers a complete range of solutions to elevate your throughput while achieving higher accuracy. Apart from Nidek, Satishloh also offers highly innovative edging solutions for your lab.